Experience the groundbreaking new detector technology with best-ever accuracy, for the most efficient measurements of kVp, HVL, dose and beyond in Mammography.

X-ray Diagnostic Mammography

In mammography screening, high-quality diagnostic images are required to ensure effective breast cancer detection. X-ray quality assurance plays a pivotal role in this process, ensuring that image quality is maximized for enhanced interpretation of mammograms, and that patient dose is minimized during examination.

Clinical mammography systems have the broadest range of radiation qualities (target and filter combinations used in X-ray production) compared to other X-ray modalities, with challenges in providing the necessary contrast in soft tissue (typically in the 18-39kV range), while also providing contrast-enhanced mammography (typically in the 40-49 kV range). As Full Field Digital Mammography (FFDM) is used in screening the population, patient dose for each image is a vital factor, and therefore having the right QA solution is important; that is where Mako comes in.

QA in Mammography

Accurate measurements of the X-ray output, such as kV, half-value layer (HVL), dose, dose rate and exposure time, become critical for ensuring the balance between image quality and patient dose. In line with these measurements, and in line with international standards, calculations such as average glandular dose (AGD; or mean glandular dose, MGD) and absorbed dose are frequently performed.

Accuracy with Mako

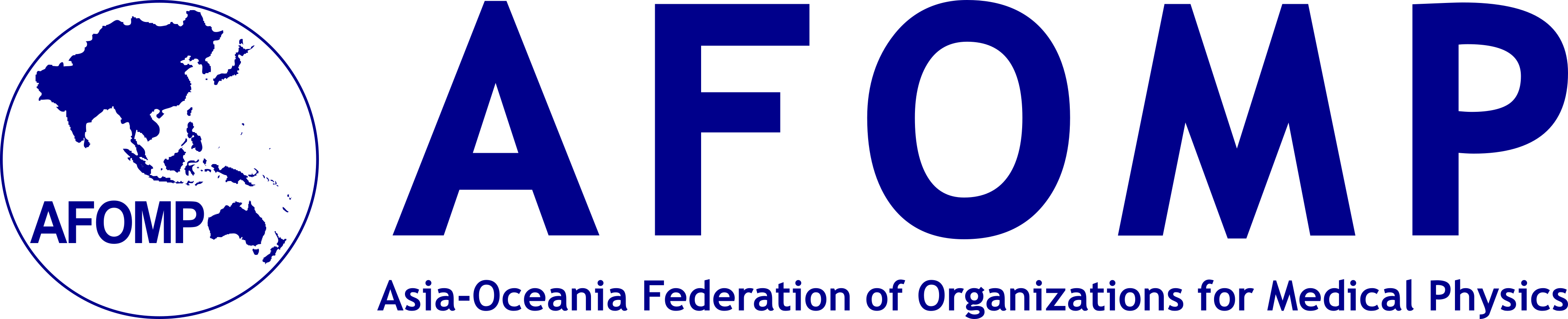

With over 40-years of experience in diagnostic X-ray QA, and the vision of “Setting the standard for X-ray QA”, RTI Group have launched the groundbreaking new Mako meter, which has its own dedicated ‘Mako Mammo Probe’. The new Mako Mammo Probe covers the entire clinical kV range from 18-49 kV (unlike other sensors, which require change to an ‘R/F’ sensor above 40kV), meaning that the entire range of QA measurements, including for the contrast-enhanced mammography, are completed with a single Probe setup.

Mako Mammo Probe has industry leading accuracy (kV uncertainty of ±1.5% or 0.5 kV) across the entire kV range, thanks to its groundbreaking new detector design, and has been built to handle the latest target/filter combinations on the X-ray mammography diagnostic market, including Ti (titanium) filters up to 1.5mm (and Aluminum, Rhodium, Silver, Copper & Molybdenum in their varying combinations and ranges).

Efficiency with Mako

Ensuring accurate QA measurement involves removing complexity for the user, to eliminate any potential mistakes. Mako has been designed to eliminate potential user error and provide accurate readings. With the range of manufacturers, target/filter combinations and tests to perform, physicists and engineers may ask the questions, “shall I remove the compression paddle?”, “do I have to orient the meter in a specific direction?”, or “can this meter handle all kV ranges?” while setting up their QA process.

Mako eliminates the uncertainty to provide the ultimate user experience. The Mammo Probe is orientation independent and immune to the heel effect, meaning users can place the Probe in any position/orientation without affecting measurement accuracy (note – users should of course follow relevant guidelines for exact positioning of the Probe, such as 6cm from the chest wall (EUREF); or 4cm from the chest wall in US (ACR), for relevant measurements).

In addition, users do not need to worry about the presence, or position, of the compression paddle – Mako will automatically sense it and provide accurate readings whether it is in place or not. Mako handles all clinical kV ranges and provides all readings of kV, HVL, dose, dose rate & exposure time with every shot, together with kV waveforms and dose rate waveforms, so no detail goes unnoticed.

Versatility with Mako

Mako can be used as a fully wireless QA solution by docking the Mammo Probe into the Mako Base Unit. The Base Unit has integrated Bluetooth, meaning immediate display of measured valuesto the Mako display device at the X-ray system controls, without the need for long wires. The Mammo Probe can also connect to the Mako Base Unit via USB cable, so that users can place just the Probe on the detector plate, for ‘fine-tuning’ of the Probe position.

Mako in Tomosynthesis

Tomosynthesis (3D Mammo) is used to provide depth perspective to mammography images, helping to improve diagnosis. The X-ray tube moves to acquire images from multiple angles and multiple images typically results in higher doses than standard 2D mammograms.

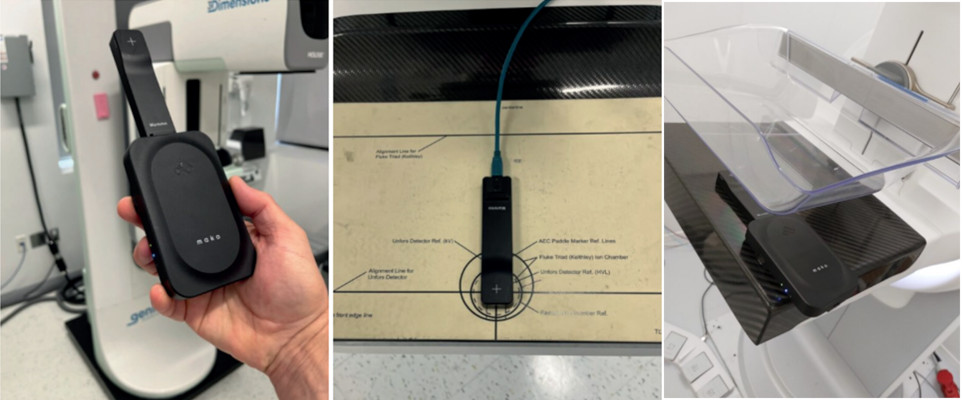

Being able to measure dose in wide angular ranges is important for the QA process, and the groundbreaking detector design with Mako provides the widest angular measurement, for accurate results even during tomosynthesis acquisition (up to ±30° angle without compromising on accuracy for dose, dose rate and HVL; and Mako can measure wider still). This means that users can acquire dose measurements in 2D and 3D mode without moving the Probe, and still acquire all the necessary accurate measurements.

Industry-leading QA software

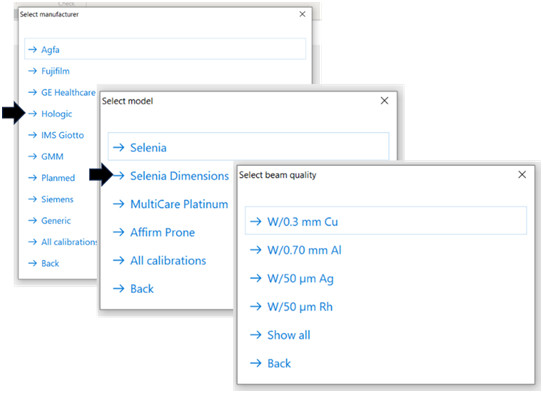

Mako connects to Ocean Next software on the Mako display device (can be any Windows tablet or PC, win10/11). Ocean software has the intuitive ‘Quick Check’ display, showing measured parameters and waveforms. Ocean makes it simple and efficient for users, while also ensuring that the correct calibration is applied. When connecting Mako Probe, the user simply has to choose the manufacturer of the system, then the model, and the relevant calibrations are shown; this avoids potential error and fulfils guidelines such as ACR recommendations “The medical physicist should ensure that the HVL has been determined for the target/filter and kVp combination used (…)”.

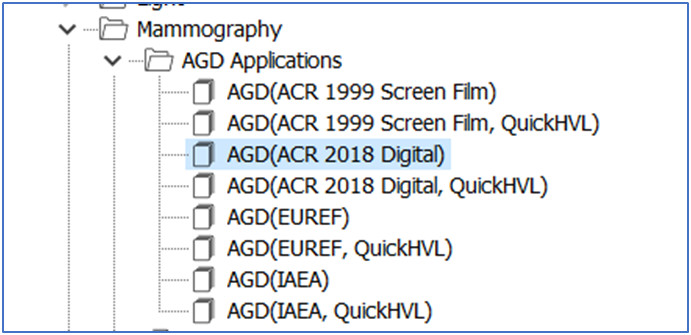

Ocean software has been developed to make QA measurement simple, efficient and traceable. In addition to the user-friendly ‘Quick Check’, there are a wide range of automated workflows (Ocean templates) already built-in, such as for AGD calculation (using ACR, EUREF, and/or IAEA methodologies), Combo Mode (such as using dual-energy acquisition for contrast-enhanced mammography), constancy tests, mAs/dose linearity tests and much more – “It’s like having Excel within the software”. By automating the calculations within Ocean software, not only is efficiency increased but also traceability, as the whole chain from exposure – to calculation – to report, is all accurate & traceable.

Michael Olding, PhD, is Head of Product Management at RTI Group. Michael works on the interface between product development at RTI and global end users of RTI’s products & solutions (physicists, engineers and medical professionals), and is passionate about ensuring user needs are at the forefront of new product development at RTI Group.