In the rapidly evolving landscape of medical imaging, Computed Tomography (CT) has become an indispensable diagnostic tool. As CT technology advances, ensuring precise calibration and quality assurance (QA) becomes paramount to maintaining image accuracy and patient safety. RTI Group, a leader in X-ray QA solutions with over 40 years of experience, addresses these challenges with its state-of-the-art CT calibration probes and measurement tools, designed to meet the rigorous demands of modern imaging environments and streamline testing.

With the launch of the latest X-ray meter, Mako, RTI Group further strengthens CT dosimetry and X-ray testing capabilities with the most advanced CT testing tools available. The RTI Mako system measures all parameters needed for routine testing, including kV measurements (on the couch or on the gantry) with industry-leading accuracy of the Mako R/F Probe, typical CT Dose Index with the RTI CT Ion Chamber, and streamlined tests of CTDI, DLP, and FWHM with the patented RTI CT Dose Profiler, either free-in-air or in phantom. RTI also provides regulation-size CTDI phantoms and leading Ocean Next software for an all-in-one premium solution.

A range of parameters influence the uncertainty of CTDI measurement in axial scans. Two particular factors pertaining to the Ion Chamber include:

- Energy dependence

- Effective length

Different manufacturers show variation in effective length from 97 mm to 117 mm, with an estimated uncertainty of ±1 mm.

For that reason, the RTI CT Ion Chamber has been built with outstanding energy linearity, within 0.5% in the range of 70–150 kV for the IEC 61267 radiation qualities RQR 5 to 10, RQA 5 to 10, and RQT 8 to 10, as well as ISO N-150. This applies for soft radiation (low HVL) as well as highly attenuated radiation (high HVL). With an effective length that is very precise (100 ±0.5 mm), a chamber that is traceable to primary standards, and integration with the advanced electrometer in the Mako system, users can be confident they are getting a premium solution for CT dosimetry.

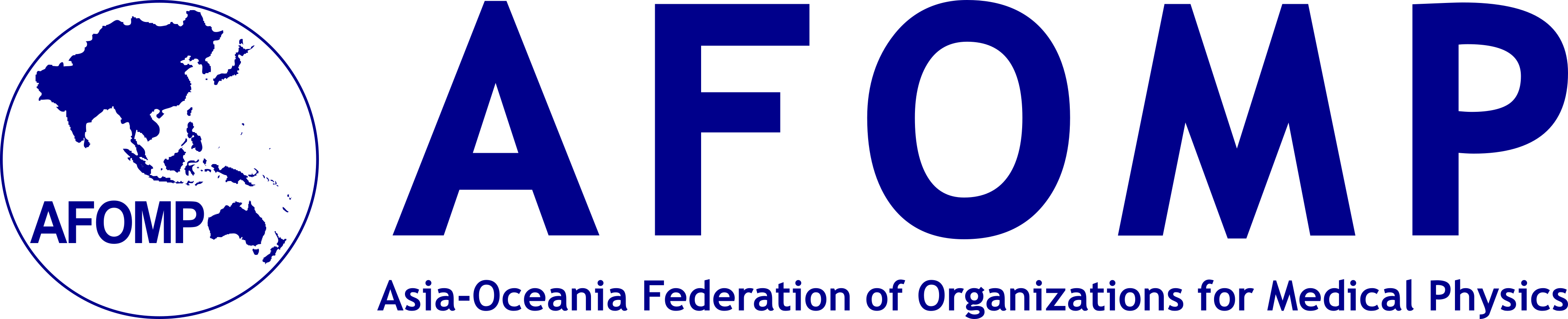

To further enhance the efficiency of CTDI testing, the RTI Ocean Next software has built-in measurement protocol templates that automate and streamline typical CTDI measurements. For example, the procedure of 1 axial scan in the isocenter of the PMMA CTDI phantom, and 4 scans in the periphery, can be fully automated in Ocean Next with fully traceable reporting. The weighted CTDI is calculated automatically upon completion of the 5 scans. Templates can be customized to any routine and setup.

Over the past decade, there has been increased discussion about the testing of wider beams in CT, and how the CTDI100 formalism applies. As technology has advanced, wider beams in CT combined with helical scanning have placed more demands on CT dosimetry testing, to ensure the CT Dose Index measurement provides a solid foundation for calculating patient or effective dose.

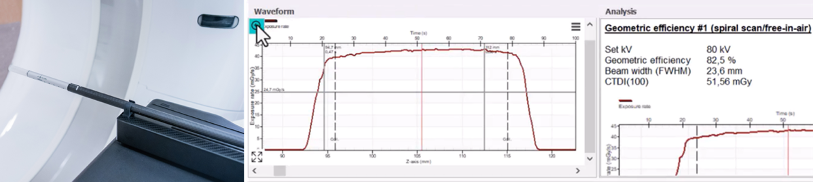

The patented RTI CT Dose Profiler (CTDP) was built to overcome such challenges and streamline routine testing. The CT Dose Profiler has the same form factor as an Ion Chamber (fitting into standard CTDI phantoms) but uses solid-state technology with a point-dose detector. It can be moved through the beam, such as in a helical scan, to obtain dose data throughout the entire scan profile—overcoming the traditional drawbacks of an Ion Chamber and avoiding multiple scans.

The CT Dose Profiler provides a visible view of the dose profile. When scanned in the isocenter of the CTDI phantom, a single helical scan provides the weighted CTDI measurement (typically requiring 5 axial scans with an Ion Chamber), which streamlines routine testing. When scanning free-in-air, the CT Dose Profiler also provides information on geometric efficiency, beam width (full-width-half-maximum; FWHM), and CTDI100 in mGy, making it a unique tool in CT scanner testing and dosimetry.

Bringing It All Together

RTI Group’s advanced tools—Mako, CT Ion Chamber, CT Dose Profiler, and Ocean Next software—offer a complete solution for accurate, efficient CT quality assurance. Together, they simplify testing, support compliance, and enhance patient safety.

Michael Olding, PhD, is Head of Product Management at RTI Group. Michael works at the interface between product development at RTI and global end users of RTI’s products and solutions (physicists, engineers, and medical professionals), and is passionate about ensuring user needs are at the forefront of new product development at RTI Group.